Applications for

industrial Control

Rooms & Monitoring

Production Line

For Industry 4.0

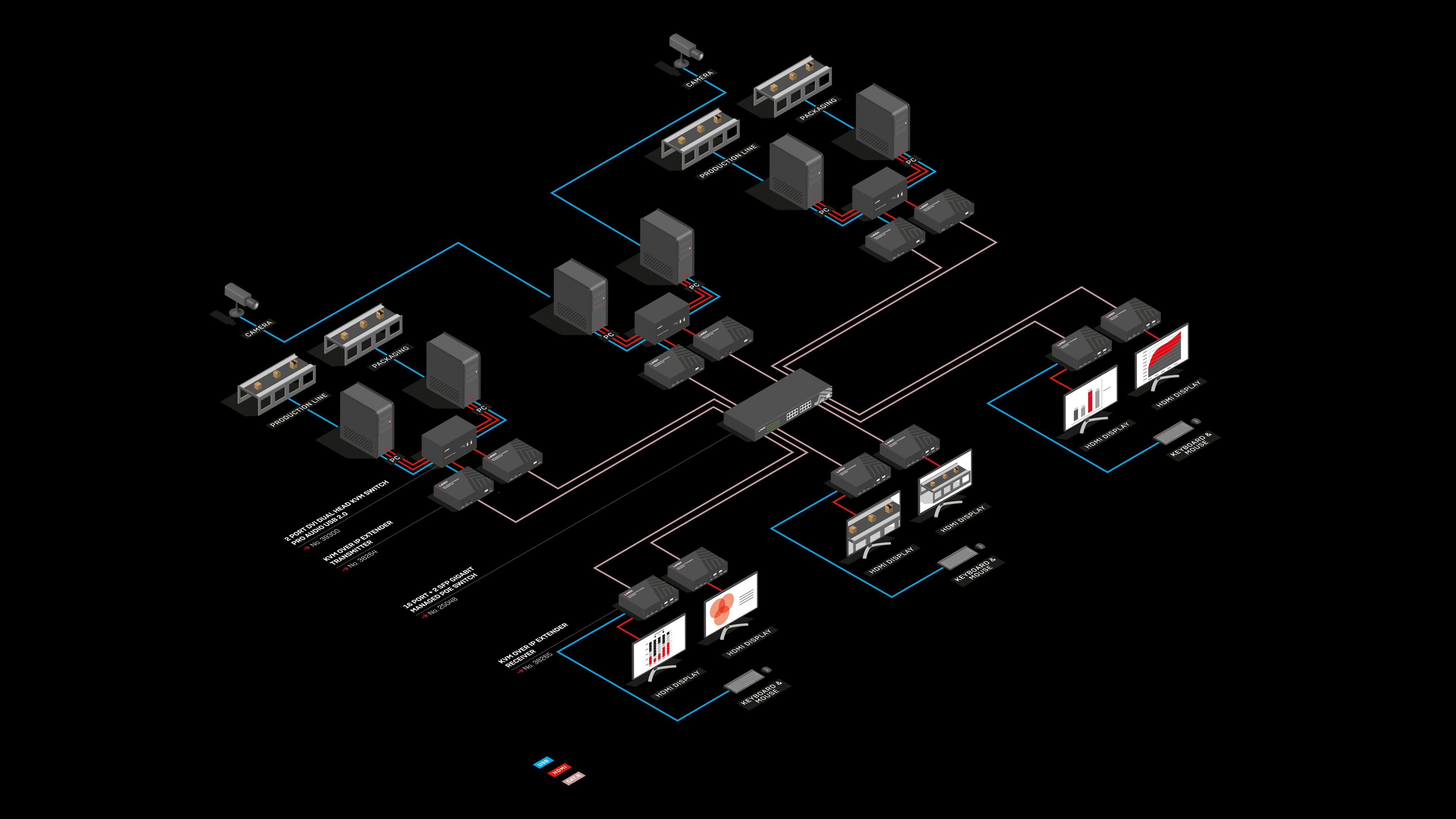

Monitoring, interactive control and regulation of automated production processes are the most basic and important function blocks of industrial 4.0 environments. Monitoring is a vital process as a supplier of manipulated variable values in the control loops of such environments.

Reliable KVM systems provide control options to centralised displays or PC’s which are long distances away from production lines and monitoring cameras in manufacturing or production environments. In most instances remote control rooms are responsible for controlling an entire production facility, therefore the reliable, flexible control options KVM solutions allow are unavoidable in these scenarios.

Multiple AV Content

Transmitted via IP Network

In scenarios such as the one shown here, where the need to use multiple sources necessitates the transmission of multiple streams of AV content, it makes sense to consider IP-based solutions when choosing the transmission medium. They provide an easy way to bridge long distances and establish multiple connections using cost-effective cable infrastructure that is usually already available on site.

The KVM over IP Extender System enables the transmission of HDMI 1.4 AV content up to 4K (3840x2160p@30Hz) over distances up to 150m using an existing Gigabit network. In its capacity as a KVM extender, it also allows full keyboard and mouse access via USB from the source device. Due to integrated HDCP 1.4, even copy-protected content is not excluded from transmission.

Depending on the requirements of the installation, either direct point-to-point or point-to-multipoint applications can be implemented. Of course, it is not necessary to use existing networks. As shown in this solution, a dedicated IP network for the application purpose can be set up with the help of a Gigabit switch.

INDUSTRY SCENARIO – PRODUCTION LINE

CONTROL AND MONITORING

All Data at a Glance

Dual-Head Components

In the solution created for these scenarios, a total of four production lines and two (or more) surveillance cameras are each controlled by a computer system via USB connection. Due to the large number of parameters that need to be monitored, monitoring data from the production lines and images from the cameras are shown on two displays per computer.

Two PCs are alternately switchable via a KVM switch in console access. To allow the content of two displays coming from each computer to be switched, the switch is designed as a dual-head version with two AV channels. The HDMI signals from the computer systems can be converted directly at the KVM switches with the help of simple adapters to the DVI connectors required for the KVM switches and back to HDMI directly behind the switch.

The extender systems, which provide the AV and console connection over the long distance between production lines and the control room, are IP-based KVM systems. In addition to the two AV channels, these systems also transport the USB signals for keyboard and mouse due to their KVM capability.

Double Switch

Dual Head KVM Switch

The 2 Port DVI Dual Head KVM Switch switches the USB, audio and two DVI-I signals of two PCs to a complete workstation with keyboard, mouse, audio boxes and 2 displays at the touch of a button on the device or via keyboard hotkey. It supports DVI single link resolutions up to 1920×1200@60Hz. Switching by keyboard hotkey allows the workstation to be installed away from the computer systems over greater distances with the aid of a suitable extender system, as in the solution shown.

An integrated USB 2.0 hub also allows the connection of further USB peripherals, which – like the audio channel – can either be switched with each switching operation or permanently assigned to one of the two connected computer systems. This allows flexible configuration and application possibilities.